Researchers and engineers have integrated a CrystalDirect harvester into the fully automated beamline MASSIF-1, a unique combination of structural biology technologies that is now open to external academic users

This is an exciting time for structural biology technology development in Grenoble. Several researchers and engineers from the McCarthy, Marquez, and Instrumentation teams at EMBL Grenoble, together with the Structural Biology group at the European Synchrotron Radiation Facility (ESRF), have been working over the past year to enhance the workflows and modalities of MASSIF-1, a fully automated beamline dedicated to macromolecular crystallography, jointly operated by EMBL and the ESRF.

To bring closer integration with the scientific services offered at the EMBL High-Throughput Crystallisation Facility (HTX Facility), they have integrated a CrystalDirect harvester into the experimental room of the beamline, enabling a complete automation of crystal delivery, from the crystals grown on plates to data collection at the beamline (‘from plate to beam’), and opening new experimental opportunities. The team recently completed the set-up of this new configuration, now open to academic users.

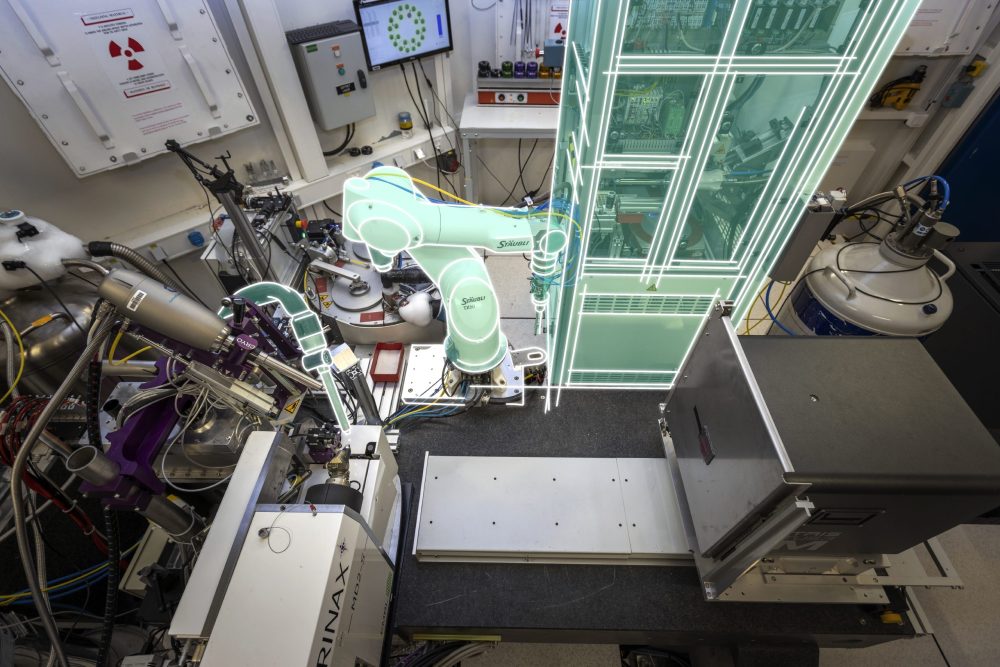

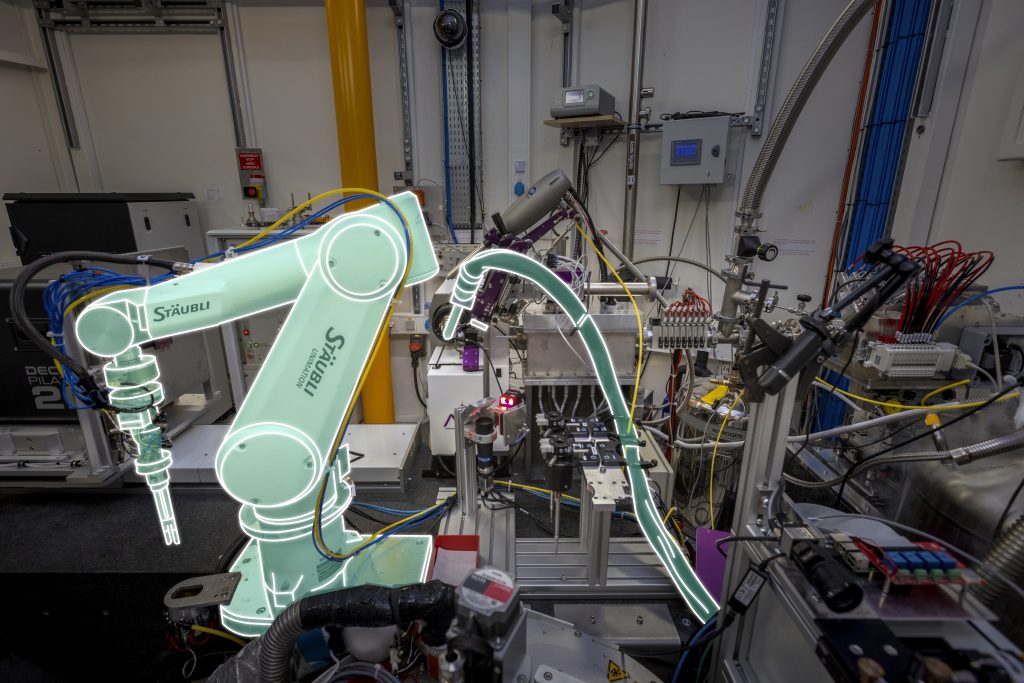

Grafting a fine-tuned robot to the beamline

Macromolecular crystallography is one of the techniques used to determine the 3D structures of macromolecules, like proteins, by shooting X-rays at regularly structured arrays of molecules, packed together in a crystal. The whole process involves several manual steps, including growing the crystal, harvesting and preparing the crystalline samples, and performing the experiments at the synchrotron beamline.

Some of these steps have been progressively automated over the past years thanks to technological innovations developed at EMBL Grenoble by the Instrumentation team, in collaboration with the Marquez Team, which has developed and operates the HTX Facility, and the McCarthy team, which jointly operates EMBL-ESRF beamlines.

The CrystalDirect technology consists of an extremely precise robot that streamlines the step of crystal sample harvesting and preparation for X-ray diffraction at the beamline. It automatically harvests the crystal from the crystallisation plate where it has been grown, and preserves the crystal sample by cryo-cooling it.

This technology was first implemented at the HTX Lab at EMBL Grenoble, which provides access to automated protein-to-structure workflows and X-ray based fragment and ligand screening pipelines for structure based drug design to users in academia and industry. However, manual steps were still needed to physically transport the cryo-cooled crystal samples to the beamline at the ESRF – until now.

The integration of a CrystalDirect robotic harvester into the experimental hutch of MASSIF-1 with its data collection pipeline contributes to streamlining operations and therefore opens the opportunity to support new types of experiments. The teams have explored new possibilities to further improve the associated workflows and experimental modalities.

A fully automated ‘from plate to beam’ service open to academic users

Already considered one of a kind for being the only fully automated beamline dedicated to structural biology worldwide, MASSIF-1 has been delivering high quality and reliability data collection and drug screening capabilities for academic researchers and the pharmaceutical industry.

The integration of the CrystalDirect technology into MASSIF-1 improves the beamline capacities even more, now offering a completely automated ‘plate-to-beam’ service, remotely accessible to the users.

During the process of integrating the CrystalDirect workflows into the beamline pipelines, the teams have been working on fine-tuning the processes to speed them up and increase the number of crystal samples being handled at the same time. The beamline is now able to harvest crystals and collect data simultaneously.

New experimental modalities will also be available, such as high-throughput room temperature data collection for a better understanding of protein dynamics, and automated crystal dehydration experiments to improve crystal quality parameters.

“This is a brilliant example of yet another fruitful collaboration between EMBL and ESRF in developing innovative state-of-the-art instruments for structural biology. Being able to completely automate processes from crystal preparation to structure determination is mind-blowing. This new pipeline will boost both in-house research and will be most valuable for our user community,” said Kristina Djinovic-Carugo, Head of EMBL Grenoble.

After several months of testing the new configuration, pipelines, and processes during the day, while the regular data collection was scheduled at night thanks to the beamline automated workflows, the ‘enhanced version’ of MASSIF-1 is now open to academic users.

This article was first published on EMBL News