Florent Cipriani, who recently retired as Head of the Instrumentation Team after a long career at EMBL Grenoble, is one of the pioneers of instrumentation development in this field, creating ingenious inventions with worldwide impact.

by Mylène André

Scientific breakthroughs are often only made possible by innovative technological developments. This is certainly true in structural biology, where researchers seek to gain insight into biological processes by determining the structure of macromolecules at the atomic level, for instance by X-ray crystallography or cryo-electron microscopy. Florent Cipriani, who recently retired as Head of the Instrumentation Team after a long career at EMBL Grenoble, is one of the pioneers of instrumentation development in this field, creating ingenious inventions with worldwide impact.

Florent, a French engineer, joined EMBL Grenoble in 1992. At that time, there was a small Instrumentation Team dedicated to supporting the development of structural biology methods for neutron sources, thanks to a collaboration with the Institut Laue–Langevin on Grenoble’s European Photon and Neutron (EPN) Science Campus. With the opening of the first high-brilliance, third-generation synchrotron source at the European Synchrotron Radiation Facility (ESRF) on the campus in 1994, the intense X-ray beams opened up new opportunities for structure determination by X-ray crystallography, for instance using much smaller crystals. At the same time, they posed severe technological challenges in terms of how to exploit them.

From manual to automatic

X-ray crystallography involves shooting X-rays at regularly structured arrays of molecules, packed together in a protein crystal, to determine their structure. When the ESRF opened, the entire operation of sample handling on macromolecular crystallography beamlines was done manually. The starting point of one of Florent’s most well-known innovations was a request from structural biologist Stephen Cusack, Head of EMBL Grenoble, who was trying to determine a protein structure from tiny microcrystals using the ESRF’s ID13 microfocus beamline. The challenge: aligning a crystal 2 microns (two-thousandths of a millimetre) in size within an X-ray beam 10 microns wide, and maintaining this alignment as the crystal is rotated in the X-ray beam, all the while shooting it with X-rays.

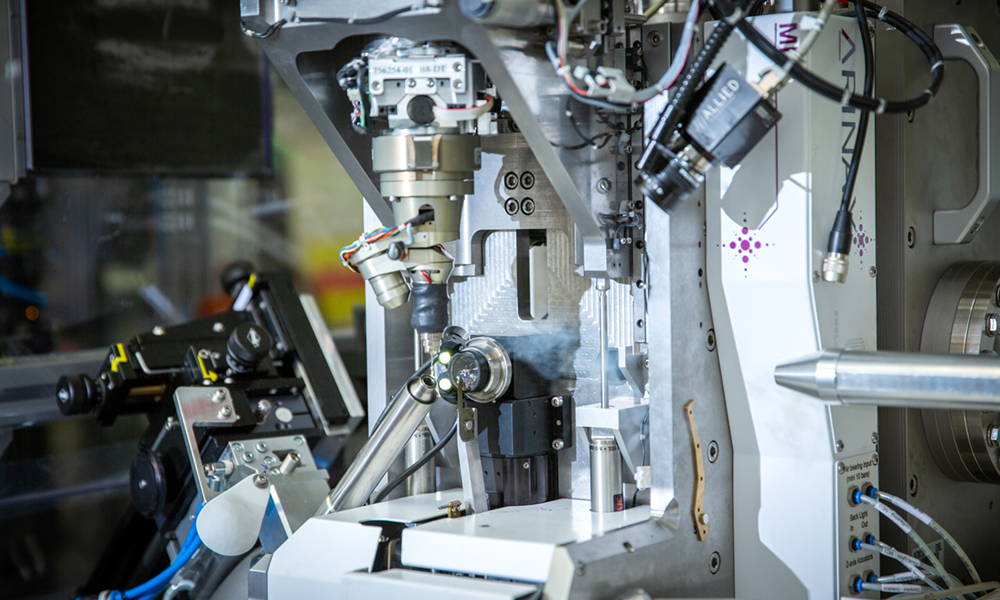

Florent, together with Tassos Perrakis – then a staff scientist at EMBL Grenoble – and Stephen Cusack, led the development of a first-generation automated micro-diffractometer. “This device, very cleverly, included a digital camera that observed the crystal at high magnification along the same direction the X-ray beam is travelling, allowing the automated and precise positioning of the protein crystal in the beam. This was a revolution,” says Stephen. The micro-diffractometer concept was patented and improved versions (called MD2 and MD3) are now in use at synchrotrons all over the world. Alongside this instrument, Florent created a first-generation automated sample changer, SC3, to accelerate the process of exchanging the crystals to be exposed to the beam. Instead of manually exchanging each crystal, this robot made it possible to load, one by one, up to 50 crystals into the beam, without manual intervention. The challenge here is that the crystals have to be kept frozen at the temperature of liquid nitrogen (−196 °C) throughout the transfer, since at room temperature they are too rapidly destroyed by the X-ray beam. The latest version of the sample changer (FlexHCD) has a capacity of 368 crystals. Both iconic innovations, and their subsequent upgrades, have not only been incredibly time saving, improving the efficiency with which the scarce X-ray beamtime can be used, but have also improved data quality and enabled structure determination on smaller and smaller crystals. “The process of obtaining enough X-ray data to determine a protein structure decreased from many hours to only a few minutes, and more recently takes only a fraction of a second. With the new fourth generation of synchrotrons like the ESRF-EBS, a complete dataset can be collected in a few milliseconds,” explains Florent.

Working together

These innovations set the stage for a complete automation of the structure determination process. As Head of the Instrumentation Team, Florent worked closely with other technology-oriented teams at EMBL Grenoble and with the ESRF Structural Biology Group, merging technological innovation with software developments. One achievement was to completely automate data collection on one of the structural biology beamlines, MASSIF-1, eliminating user intervention completely. A second example is the joint development with the Márquez Team of the CrystalDirect robot, a unique instrument in the world, capable of automatically harvesting crystals from their growth medium and freezing them at liquid nitrogen temperatures. This led to the development of automated crystallography pipelines, which can be remotely controlled through the Crystallographic Information Management System software. A CrystalDirect robot will soon be incorporated directly into MASSIF-1, allowing the research community to put a crystallisation facility and a synchrotron remotely in every lab.

Over the years, Florent has played an active part in the close collaboration with EMBL’s site in Hamburg, which also specialises in structural biology and operates synchrotron beamlines. Florent was a member of the executive committee in charge of constructing the Hamburg synchrotron’s newest beamline, PETRA III. He also led the development of several new instruments, including the ultrahigh-precision MD3 micro-diffractometer and an automated sample changer for use in biological small-angle X-ray scattering (Bio-SAXS) – another method for analysing the structures of biological materials. Bio-SAXS requires a protein solution instead of a protein crystal. It therefore has different kinds of requirements, such as the ability to easily collect the liquid, expose it, and circulate it in the beam. A three-year project finally led to a machine that could carry out these processes automatically. “These innovations are directly reflected in the data quality: the better your instruments are, the better your data and the resolution of your pictures of molecules will be,” says Thomas Schneider, a group leader at EMBL Hamburg, who worked closely with Florent. Rapid cycles of design and testing of prototypes at EMBL made these innovations possible.

Innovations adopted worldwide

Ease of use by researchers is at the heart of the technology Florent developed. “Florent really understands what we need. He is tireless in looking for technological solutions and manages to put things together in a way that is easy to use. This is a service for the whole science community,” says Thomas Schneider. This adjustment to users’ needs is one of the reasons why EMBL Grenoble’s services and facilities are widely used by the scientific community and also by industry, such as pharmaceutical companies. It’s also why instruments like MD2 – and later MD3 – have now been adopted by other synchrotrons all around the world.

With the support of EMBL’s technology transfer partner, EMBLEM, the Cipriani Team has patented several innovations and developed collaborations with companies to industrialise their prototypes: principally with Maatel (now Arinax), a French company based in Grenoble with a unique specialisation in mechanics, electronics, and computer science, and also with MiTeGen and Molecular Dimensions. Ralf Siebrecht, CEO of Arinax, underlines the importance of the trust and shared values between EMBL Grenoble and Arinax, which Florent played an important role in building. “At Arinax, we are aware of this symbiosis that works very well with EMBL. Today, EMBL is very much aware of what to entrust to us, and we also know in return that we can have confidence in EMBL’s projects,” he says. Ralf also emphasises the special working environment at EMBL, which has enabled the Instrumentation Team to grow and support the needs of the technology development cycle: the emergence of a need from a scientist, the development of an innovation, and use by the research community, leading to validation of the new technology.

Florent is passionate about his profession. “It’s exciting work from a technical point of view,” he says, “but also in the relationship with the researchers. Innovations are often triggered by the needs of scientists, so making the instruments useful and ergonomic for the scientific community is very stimulating and gives a lot of satisfaction to the job. This is the common thread running through all these developments.”

This article was originally published on EMBL News